PRODUCT

PRODUCTS

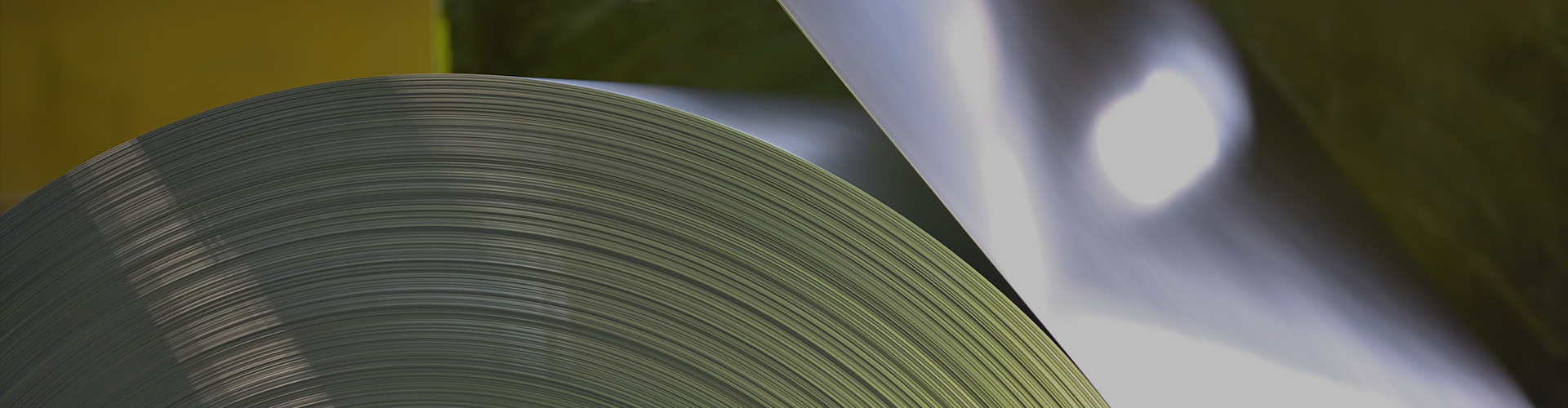

AegisArt®pre-anodized Aluminium Sheet & Coil

The Description Of Anodizing

AegisArt® Pre-Anodizing is an electro-chemical process used to create a protective film of aluminium oxide on the surface of aluminium extrusion or sheet. As the aluminium oxide film is created from the aluminium itself, it is integral to the aluminium and cannot crack or peel. Anodizing is translucent giving the aluminium a deep metallic luster and is extremely durable and continues to stand the test of time.

The Advantage Of Anodizing

Anti-scratching and surface hardness up to sapphire's grade

Good Corrosion Resistance

Non-combustible

Anti-fingerprint

100% Recyclable

Easy maintenance

THE DIFFERENCE OF COIL ANODIZING AND SHEET ANODIZING.

Continuous Anodizing:

Process is tightly controlled creating a uniform anodizing layer resulting in a very consistent surface appearance and elegant colors, no visible iridescence.

The Sheets Batch Anodizing:

An electrical contact must be made on each part which causes a rack mark, or punch some holes on each side of aluminum sheet to facilitate the mounting of the hanger or fixture, the material loss is high. The sheet batch anodizing is limited by the size of the oxidation tank, lower production efficiency, and it is likely to produce visible color differences.

Technical Parameter

|

Grade/Temper |

1050-H16/1070-H16/1085-H18/1100-H16/3003-H24/5052-H32/5005-H14 |

|---|---|

|

Thickness |

0.3~3mm |

|

Width |

20-2000mm |

|

Surface Process |

Continuous Anodizing, electrolytic coloring and anodizing dyeing |

|

Surface |

Satin, Matte, Glossy, High Reflective, Brush |

|

Color |

Silver, Gold, Light Champagne Gold, Iron Grey, Brown Bronze, Matte Black, Imitation Stainless Steel |

|

Film Thickness |

AA5-AA10(Indoor≥5μm),AA15-AA25(Outdoor≥15μm) |

|

Hardness |

≥9H |

|

Total Reflectivity |

≥82% |

|

Color Difference |

No color difference by visual inspection, and the color difference value of the same aluminum coil △E≤1.0 |

|

Gloss |

Deviation of the same batch is smaller than 10 |

|

Hole Sealing Quality |

≤30 mg/ d㎡ |

|

Abrasion Resistance |

Sand Fall≥330 g/ μm; Sand Blasting≥3.5 S/ μm; |

|

Heat crack resistance |

≥80℃ no crack |

|

Corrosion resistance |

Indoor plate (more than 72 hours 5%NaCl spray test); |

|

Resistance to Accelerating Weathering |

Test Time≥4000h, Color Difference △E≤5.0. Other aging property is not less than 0 grade. |

|

Standard |

EN 573-3 ,T/CBMF113-2021 |

AegisArt? Stain Series

AegisArt® Anodizing is renowned for durability in salt water environments. AegisArt facade materials has been engine-eered to maximize these features and is even harder, denser and more durable.

N91505

Sliver

N91505?50-2

Sliver Green

N91505?16

Stainless

N91505?15-3

Slat Grey

N91505?15-6

Charcoal Grey

N91505?40-7

Steel Blue

N91505?40-4

Medium Blue

N91505?40-2

Azure Blue

N91505?50-2

Bean Green

N91505?50-4

Grass Green

N91505?50-8

Dark Green

N91505?50-6

Wilderness

N91505?70-1

Sandstone

N91505?70-3

Beige

N91505?70-4

Pale Bronze

N91505?70-5

Light Bronze

N91505?70-6

Medium

N91505?70-8

Dark Bronze

N91505?70-9

Espresso

N91505?17

Black

N91505?15-9

Chestnut

N91505?30

Rose Gold

N91505?1

Titanium

N91505?25

Brass

Technical Parameter

|

Alloy |

5005 H14 |

Standard |

GB Standard |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

Tensile Strength/Mpa |

Yield strength/Mpa |

Elongation/% |

|||||||||

|

154 |

145 |

6.5 |

|||||||||

|

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Ni |

Zn |

Ti |

Other |

Al |

|

|

0.07 |

0.18 |

<0.01 |

0.08 |

0.85 |

0.02 |

- |

<0.01 |

- |

≤0.05 |

other |

|

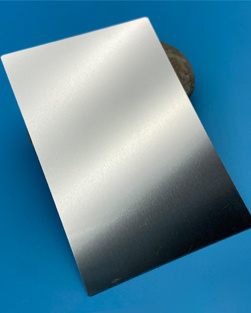

AegisArt? Matte Series

S600

S270

S600G

S280

PRODUCT INTRODUCTION

Matte anodized aluminum plate is also called Titanium silver anodized aluminum plate. The surface is anodized, so it is anti fingerprint and anti scratch. .

Technical Parameter

|

Product |

Type |

Total Reflectance[%] |

Specular Reflectance[%] |

Diffuse Reflectance[%] |

Iridescence scale 1-4 |

Alloy Purity |

||

|---|---|---|---|---|---|---|---|---|

|

ASTM E 1651 |

DIN 5036-3 |

60° long |

60° trans |

DIN 5036 - 3 |

||||

|

S600 |

matt |

85 | 85 | 70 | 65 | 66 | 3 |

Al 99.9 |

|

S600G |

Diffuse matte |

83 | 83 | 32 | 10 | 80 | 2 | 5005 |

| S270 |

stripe |

- | - |

not relevant |

- | 3 | 5005 | |

Application Cases

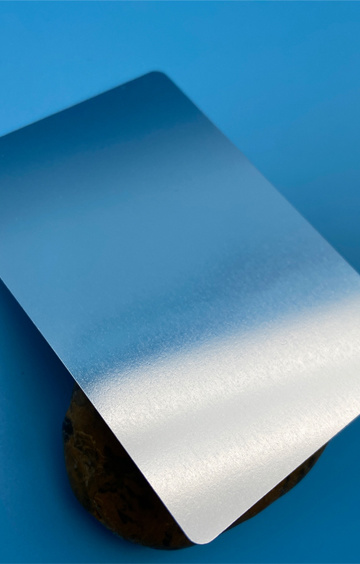

Alton? Mirror Series

ART100

Sliver Mirror

A20

Light Gold Mirror

A30

Rose Gold Mirror

A17

Black Mirror

PRODUCT INTRODUCTION

Alton? Mirror Series is refer to anodized mirror aluminum plate, which is made of 1085 pure aluminum plate with aluminum content up to 99.85% by rolling and anodizing.

Technical Parameter

|

Alloy |

1085 H18 |

Reflectance |

86% |

Standard |

EN485/2 |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Tensile Strength/Mpa |

Yield strength/Mpa |

Elongation/% |

||||||||

|

169 |

161 |

4 |

||||||||

|

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Ni |

Zn |

Ti |

Other |

Al |

|

0.035 |

0.047 |

0.001 |

0.001 |

0.0 |

0.0 |

0.002 |

<0.01 |

0.02 |

- |

≥99.85 |

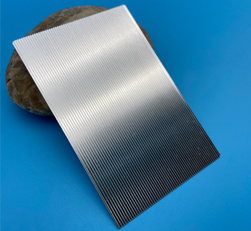

AegisArt? Brush Series

S518

S516 16

N515

N510 12

PRODUCT INTRODUCTION

Brushed anodized plate is made by brushing and anodizing on the surface of aluminum plate. According to different silk patterns, it can be divided into different silk patterns, such as long drawn plate, medium drawn plate and snowflake plate.

Special Anodized Aluminum

High Glossy

Sandblasting

Hammer

Stucco

PRODUCT INTRODUCTION

Brushed anodized plate is made by brushing and anodizing on the surface of aluminum plate. According to different silk patterns, it can be divided into different silk patterns, such as long drawn plate, medium drawn plate and snowflake plate.

Application Cases

Ceiling

Curtain Wall

Car Interior

Brand Card

Lampshade

Indoor decoration

Subscribe to our newsletter to receive exclusive information about us and our services