PRODUCT

PRODUCTS

3003 Aluminum Sheet

3003 Aluminum Sheet

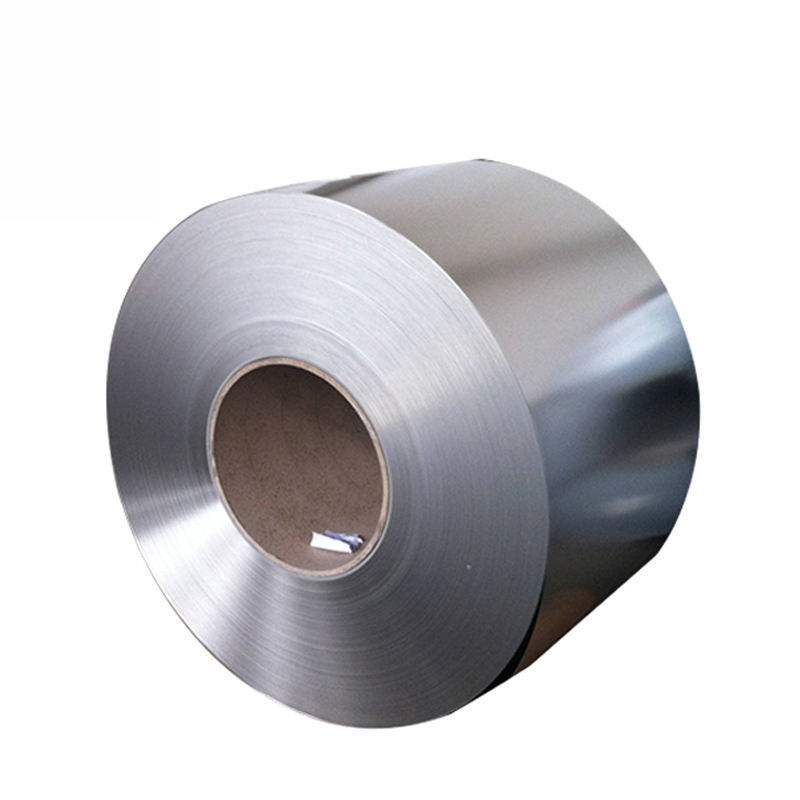

3003 aluminum sheet is a typical Al-Mn antirust alloy. The addition of the alloy component Mn increases the strength slightly while maintaining the excellent workability and corrosion resistance of pure aluminum. The 3003 aluminum sheet is a non-heat-treated alloy and cannot be strengthened by heat treatment, so the conventional cold working method can improve its mechanical properties. In addition, 3003 aluminum sheet has excellent weldability, formability and other advantages, and has become a popular and economical choice for "home appliance components".

|

Alloy |

3003 |

|---|---|

|

Temper |

F,O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H111,H112,H114, |

|

Thickness(mm) |

0.2-10 |

|

Width(mm) |

100-2650 |

|

Application |

Antenna pot material, power battery shell, automobile fuel tank, silo, door plate material, signage, |

Applications And Features:

■ Corrosion Resistance.3003 aluminum sheet has good corrosion resistance, which is close to the corrosion resistance of industrial pure aluminum. It can effectively resist the corrosion of atmosphere, fresh water, sea water, food, organic acids, gasoline, neutral inorganic salt solution, and dilute acids.

■ Corrosion Resistance.3003 aluminum sheet has good corrosion resistance, which is close to the corrosion resistance of industrial pure aluminum. It can effectively resist the corrosion of atmosphere, fresh water, sea water, food, organic acids, gasoline, neutral inorganic salt solution, and dilute acids.

Application

Polymer lithium battery

Brazed plate radiator

Heat exchanger

Soft pack lithium battery

3004 Aluminum Sheet

3004 Aluminum Sheet

3004 aluminum foil is commonly used in food and beverage.It has the advantages of light weight and gloss, good barrier properties, strong light shielding, oxidation resistance, water resistance, moisture resistance, non-toxicity and tastelessness, etc.,and meets the standards for food packaging.

|

Alloy |

3004 |

|---|---|

|

Temper |

F,O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H111,H112,H114, |

|

Thickness(mm) |

0.2-10 |

|

Width(mm) |

100-2650 |

|

Application |

Lamp head material, shutter material, heat sink, LCD back sheet material, |

Performance

■ High temperature and low temperature resistance, aluminum foil products made of 3004 aluminum foil will not cause deformation due to temperature changes.

■ Small pinholes, good air tightness, prevent food spoilage.

■ Good light shielding, can be used to package those items that need to be protected from light, such as tea, coffee, cream, etc.

■ Good light shielding, can be used to package those items that need to be protected from light, such as tea, coffee, cream, etc.

Application

Window shades

Lamp cap material

Electrical enclosure

LCD TV backplane

3005 Aluminum Sheet

3005 Aluminum Sheet

3005 aluminum sheet belongs to 3 series Al-Mn alloy with Mn content between 1.0-1.5, and 3003,3004 aluminum sheet belong to rust-proof alloy with strong corrosion resistance.Similarly,3005 aluminum sheet is also a non-heat-treated alloy, which is cold-processed to improve its mechanical properties. However, the strength of 3005 aluminum is higher than both of them. Among them, it is about 20% stronger than 3003 aluminum sheet.

|

Alloy |

3005 |

|---|---|

|

Temper |

O~H118 |

|

Thickness(mm) |

0.1~50mm |

|

Width(mm) |

1000~2000mm |

|

Application |

bus skins, silos, antenna pan materials |

Using

heat sinks, radiators, power battery enclosures, automotive heat shields, fuel tanks, water tanks, automotive skid plates, battery explosion-proof valves, battery covers, automotive interiors, signs, cans, medical equipment,

Performance

■ Excellent Corrosion Resistance.3005 aluminum sheet can resist corrosion from atmosphere, fresh water, sea water, food, organic acid, gasoline, neutral inorganic solution and so on.

■ Excellent Corrosion Resistance.3005 aluminum sheet can resist corrosion from atmosphere, fresh water, sea water, food, organic acid, gasoline, neutral inorganic solution and so on.

■ High Plasticity. In annealing temper,3005 aluminum sheet has high plasticity. In the case of semi-cold quenching, plasticity is good, while in the process of cold quenching, plasticity is the lowest.

■ High Plasticity. In annealing temper,3005 aluminum sheet has high plasticity. In the case of semi-cold quenching, plasticity is good, while in the process of cold quenching, plasticity is the lowest.

■ Mechanical Properties. The tensile strength of3005 aluminum sheet is 140-180 MPa, and the yield strength is 0.2 (MPa) ≥115.

Application

Aluminum for louvers

Aluminum substrate for color

Oxidized lamp cap material

Aluminum roll for cans

Subscribe to our newsletter to receive exclusive information about us and our services